Fabrication Shops, Yards & Dry Docks

- Specialized Personnel: Our staff (engineers, fitters, welders, electricians etc. ) has experience in complex projects, including the use of exotic materials as well as complete process modules.

- Dock: We have direct water access, allowing us to deliver extra wide/heavy modules We can manage all the logistics, delivering CIF and DDP Incoterms.

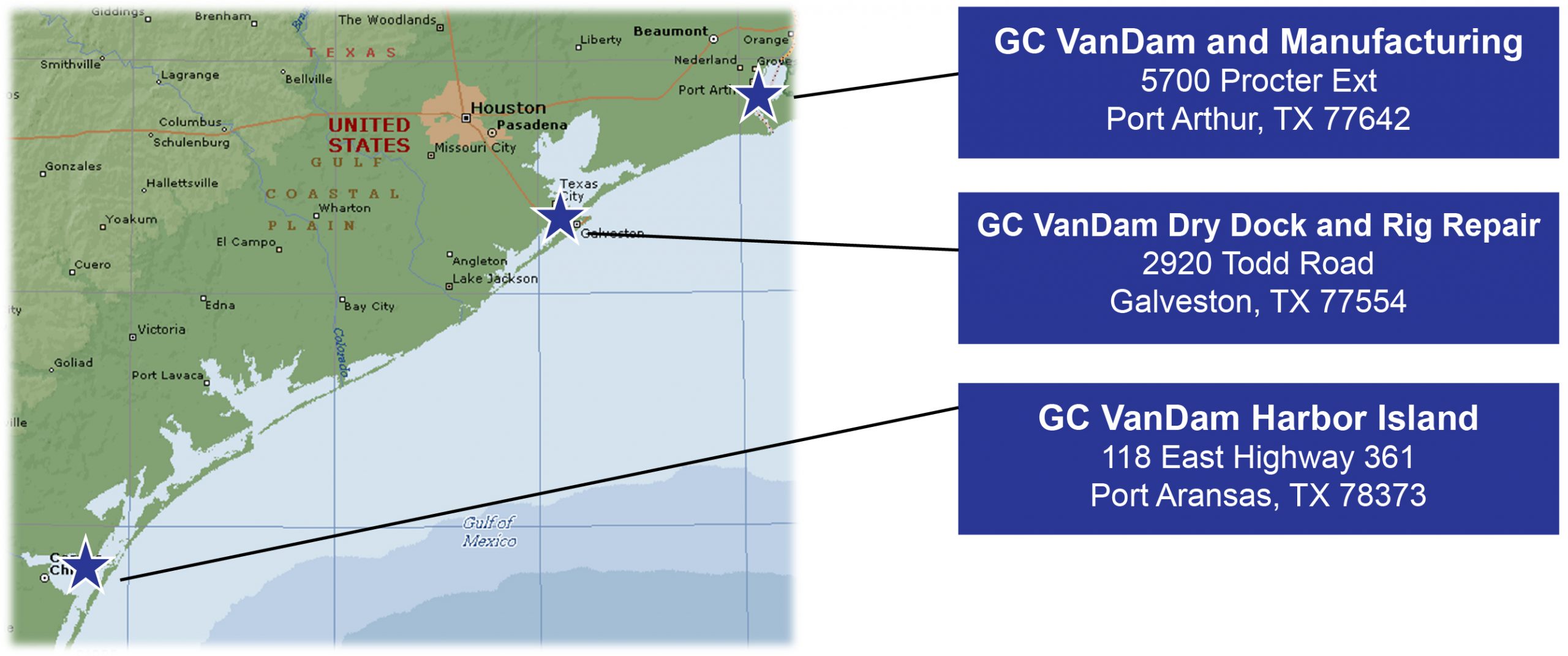

- Geographical Locations in The Gulf of Mexico: We are located near the main energy markets of Mexico, the United States, and the Caribbean, reducing the cost of transportation.

- Yard Assembly & Storage: Large capacity to store equipment in our yards, delivering according to Jobsite priorities We can assemble modules in our plants with imported parts to be exported with a possible tax advantage.

Our Yard Fabrication Shops & Drydocks

OVERVIEW PORT ARTHUR FACILITIES

- Port Arthur Central yard: 21 acres

- Port Arthur South Yard 7 acres

- Drydock #1 200’ x 84’

- Drydock # 5 275’ x 40’

- Drydock #4 384’ x 90’

EQUIPMENT & CAPABILITIES

- CNC Plate cutting- (2ea)12’ X 40’ X 6” thickness

- 400 Ton plate press break

- Plate roll up to 5/8” thick

- Plate shear up to 1/2”thick

- Programmable sawing up to 24”

- Pipe bending up to 6” diameter

- Multi bank welding machines up to 400 Amps

- Multiple overhead cranes

- Submerged arc welding capacities

- Hydrostatic testing up to 10,000 PSI

- Onsite blasting and coatings

- Rail material handling in between shops

- Open ended shop access large projects

- Multiple yard cranes (300 tons combined)

- Fully staffed machine shop

Galveston Yard has just over 100 acres with direct access to calm waters. The shipyard location is proximate to a world hub of refineries offering both easy access to Gulf Copper’s facilities & services.

GALVESTON FACILITIES

Galveston Yard has just over 100 acres

EQUIPMENT & CAPABILITIES

- 350 ‘ x 200’ Dry Dock with 1800 ton capacity

- CNC Plate cutting- (2ea)12’ X 40’ X 6” thickness

- 1000 TON CNC plate press Break

- CNC Plate roll up to 2-3/8” thick

- Plate shear up to 3/4”thick

- Programmable sawing up to 24”

- CNC Pipe and Structural bending and forming

- Multi bank welding machines up to 400 Amps

- Multiple overhead cranes (30t comb. & 75t )

- Submerged arc welding, Semi-Automated welding

- NDT, Hydrostatic testing up to 10,000 PSI

- Onsite blasting and coatings

- Open ended shop for extra-large projects

- Multiple yard cranes

- In House Welding school

- Electrical Repairs, Mechanical Repairs

- Scaffolding

- Tank Cleaning/ Environmental

GALVESTON OPERATIONS

- 100+ acre facility on Pelican Island – 9 miles from sea buoy

- Operating one large drydock approx. 25.000 ton capacity (350 x 225 ft.)

- 4.000 + feet or pier space at 25 to 35 feet of water depth

- New fabrication facility with large plasma table, plate roll and press brake

- Current level of production personnel – 400. Previously work to a maximum of 1.200 people.

- Administrative staff – 40 people

CORPUS CHRISTI FACILITY

- 219 acre facility located less than 3 NM from the Gulf of Mexico.

- 100 acres of stabilized land for cargo operations and storage.

- 3,700 linear feet of bulkhead frontage

- 20,000 square feet of covered storage

- Water depths from 20-36 feet MLLW along bulkhead

- Located on alternate route of the Intracoastal Waterway and Corpus Christi Ship Channel

AREAS AND CAPACITY FOR FABRICATION

Covered Area (Shop, Warehouse ) : 355,209 Sqf. ( 33,000 m2)

Yard (Uncovered area): 430,556 Sqf. (40,000 m2)

WORKSHOP CAPACITY

Depends on our product mix, with one million man-hours year maximum per shift, have a nominal capacity of 15,000 metric tons per year per shift.

CRANE CAPACITY

Overhead cranes : 28 cranes ( 10 ~ 20 Metric Tons cap)

Crawler cranes: 2 Cranes (45 Metric Tons cap.

FABRICATION EQUIPMENT AVAILABLE